84 degrees when I got to work, 94 when I packed up. Blue sky with some puffs. A nice breeze kept things nice. This weather report was brought to you by the City Of Pompano Beach Department of Tourism.

DURING THE WEEK.

I had worked with bougainvilla last weekend. On Monday, I noticed my right wrist was itching. Later, I recognized the allergic reaction was developing - tiny bumps all over my wrist that itched and broke when I scratched. I instantly took an antihistimine, which I knew would knock down the reaction.

When I looked on line about whether Bogainvillea was a poisonous wood, all I could find was that the leaves were not harmful in small amounts and the wood could be used as bird perches.

A friend pointed to allergic reactions. Using allergic as a search word, I found out that Bougainvillia is a relitive of Poison Ivy. My search mostly told about getting pricked by the thorns. The sap is what is reactive.

It was one thing to just grab the wood to toss it in a pile. It is another to have the saw dust, both from turning it and griinding on it. What really confuses me is the fact that my left arm got more covered than my right arm did.

What you are supposed to do is to wash your exposed skin with soap and water immideatly after exposure to remove the toxins. Since I did not do that, and had the dust on my skin for extended time, I am self medicating myself by taking antihistimines and applying a steriodal cream, both only when I feel any itching. It seems to be working.

I sent out a warning to the turning club I am a member of. If one covers up and washes immideately afterword, there should be no problem working the wood.

I decided to hold off on any sanding of my bowls until the wood dries some. I gave the "nut bowl" them some varnish to stiffen the fibers so it could be sanded. I will wait a week or two before I work the surfaces.

I think it is much like Brazillian pepper, which is also in the Poison Ivy family, where once the wood has dried, it will be more than safe to work with. One just has to wait until it is dry.

FRIDAY

I was looking for something I need. I decided the walk in closet was a good place to search. First thing I was reminded of was that I have a lot of boxes of old papers and bills. I pulled them out of the closet. Also any clothes on the floor got tossed in the hamper. I found a jacket that my mom made for me when I was a teen and it fits. It is a just fit, but fits. I located some old charcoal drawings I did back in the 80s. I never found what I was looking for.

I now have to figure out what I did with my paper shredder. Until then, I will sort through the boxes and fill some bags of old bills that I don't need to hang onto any more.

SATURDAY

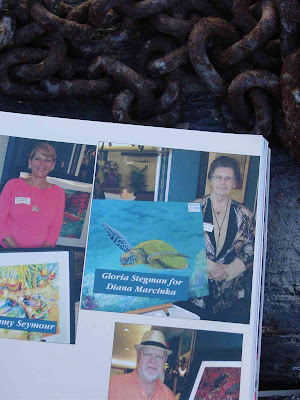

During our art show, a photographer for the LIGHT HOUSE POINT MAGAZINE came around and took our pictures.

This is a picture of my mom with artwork of one of her students who could not make it to the show.

This is a comment that includes a mention of me.

Here is a picture of me at the art show.

We stopped at a couple yard sales. I picked up a wood cutting board at one. It had some surface damage.

Later in the day, I took the sanders to it and cleaned up the surfaces, removing the old oiled wood. This will go to my niece. She needs it.

The cutting board as I got it. Notice the cuts all across the surface.

The sanded cutting board ready for a new vegetable oil finish

At a church yard sale, I saw some yarn. I knew I could get a deal for it. I did not realize how great a deal I was able to get. I have no idea what I will do with that yarn, as I am not doing that much crochet. It could amount to a life-time collection of yarn.

Later in the day, I realized I would never have time to untangle it at home, I took the time to sit and separate the whole tangle of yarn and lay it out so I could take a picture of all of it. I also wanted to know what I had. I love some of the colors.

The bag of yarn I got for $3 with the tangles

Untangled yarn from the right side of the table

Untangled yarn as seen from the left side of the table.

I have a wood turning tool that uses an allen wrench to cut into small holes. I thought I would fix the tool by machining the surfaces level and flat. After some work, I found that it is too hard a metal for the cutting bit I was trying to use. After a while I gave up on that.

While I was at it, the lathe uses a lock pin to set it at zero. That lock pin was made from a nut but was not quite machined small enough. I mounted it in the lathe and ran a file on it while it was spinning. That little bit allows the pin to fit perfectly into the centering holes without effort.

Beast of the back yard, waiting for more attention

While I had the lathe set up in the machining mode, I decided I would tackle the T-nuts I started making on the grinder. After fiddling around a tiny bit, I decided to finish them on the grinder.

With some care and measuring, I was able to get all three T-bolts made so the heads fit nicely inside the slots. I used a file to remove any burrs and to clean up the surfaces. The grinder does make the job a whole lot quicker than machining them.

I also see the T-nuts don't have to be precise. they just have to fit into the slots and be big enough that they don't twist around. It is not absolutely critical that the screws are absolutely centered, as long as they do not come into contact with the breach that the bolt sticks out. That is bigger than the bolt itself.

Finished T-nuts. One nut is in slot, shown how it is used (the one in the slot) to hold down a piece of work.

The beast of the back yard sure acted like a cat today. since I was spending most of my time sitting, He laid at my feet and soaked up what attention I gave him between work I was doing. He would have loved more, but he got quite a bit.

Tomorrow, we are having a family gathering at my brother's house. He built a forge and has an anvil. I hope to be pounding on metal tomorrow. I brought my carving basket but really don't intend to work on anything in particular. We may work on other projects too. I might cut some metal to work with on my little lathe. Beyond that and eating, I have no idea what the day will bring.

I will see what I actually do Tomorrow.

year 11, Week 20, Day Two (week 594) (January 17, 2000 was my first carving day.) 05-29-11 Sunday

I don't know the temperature. I was at my brother's house and spent my entire time beneath a spreading oak tree that killed much of the heat. A light breeze made it nice. We had mostly blue sky, clouds periodically got in front of the sun which helped. Some clouds were heavy and some were light.

Around eight in the evening, when we were pretty much done, we did get a tiny bit of liquid sunshine, but only enough to make some noise on the awning.

This weather report is brought to you by the city of Fort Lauderdale Department of Tourism.

I started early, I had a lot of food to take with me, both food I was bringing and food my mom gave me to bring. I had other things with me too. It was a big load. I wanted to get my refrigerator back.

I settled outside, and decided not to do any carving. I did mess with a piece but did not do more than mar a piece of wood. I assisted setting up an awning. The free-standing frame is light metal and everything kept coming apart when we needed to move it. We ended up dropping the legs. Once we had it in place and back together, we had to figure out how to put the tarp onto it and had it upside down twice. The instructions was written by someone who knew how to put it together.

I sat and played games on my palm pilot most of the day.

We finally fired up the forge. We were not running it the way one should, turning the blower off between heats, instead we had the blower running all the time. The blower was a heat gun where the elements had died on it. There is more that we have to do on the forge. It has more parts and pieces to be added, but we were able to do something with it.

The forge in use

My brother gave us some re-bar, reenforcing bar used in concrete, to work with. Rebar has ribs down the length to hold it. I pounded the end of the bar square, with the re-bar ribs only showing on the corners. I then narrowed the end to a blunt point.

I saw several times that I was not leaving the metal in the heat long enough. I see it lost heat fairly quickly too. I had a maximum of about a minute of pounding to get it to whatever shape it needed to be. and usually about thirty seconds. My nephew liked to use a heavy hammer and go splat on the metal, slow individual strokes. I used a lighter hammer and tapped on it quickly.

After making the point, I bent the end over. At that point, It dawned on me that we needed a coal hook to moved the coal around in the forge. I had seen a blacksmith show where that was one of the first projects he made. I flattened the bent end, making it wider. I used the technique of pulling the hammer on impact to draw the metal out to the edges. it worked as well as the books said. A bit later, My nephew said that the coal hook was quite helpful.

The finished coal rake

My nephew holding a hot bar of steel

My nephew had flattened the end of his bar, He then turned it ninety degrees and flattened the next section. He then made a second bar the same way. With my brother helping him, he heated it and used a punch in the pritcher hole in the anvil (Anvils has two holes, one is a square hole for different fittings like cutters, and one is a small round hole called the pritcher hole). They then cut a small piece of rod and fitted it into the hole, pinging the ends over into a rivet.

Harbor Freight 100 pound anvil.

After a little bit of work, they got the tongs working nicely. Because it has flat ends, it does not grab the rounds stock we were using very strongly, but it made a big difference in some work he was doing. He now has to make tongs with a rounded jaw to hold round stock and square jaws to hold square stock. At least he made something he really needed. He will have several dozen tongs when he is done.

I could have done a whole lot more work but this was all I did and I sat back down to play games. I will have to make a set of tongs next time. My nephew will be over far more often so he will be doing a lot more black smithing while I will be instead, going to my mom's house to work wood and machine metal.

Because it needed the same electrical outlet that the forge was using, we later mounted some heavy square stock into the power hacksaw to cut me a couple pieces for the cross slide I want to make.

A power hacksaw is a motor with a couple reducing pulleys, with an arm that moves a slide guided hacksaw blade back and forth. it is a wonderful machine. You get it cutting, and you can walk away while it cuts through heavy metal stock. What is great about it is that it uses standard hack saw blades and They last for dozens of cuttings, even in stainless steel. When you cut with a hacksaw by hand, you change the angle of it ever so slightly with each stroke. That twists the blade, reducing the life span of the blade by a dramatic amount. Whether it takes a couple minutes or an hour to cut through a piece of metal, the power hacksaw keeps cutting whether you are there or not. there are no sparks as you would have with a cut-off saw and if you need to do machining, the metal does not heat up very much either which would change the dimensions.

A cross slide is a tool holder for the lathe that allows you to rotate the cutting bit in my machine lathe to cut on angles. that is one tool that I desperately need on my little lathe.

I had machined some wood as a prototype of what I wanted to make my cross slide to look like. It was to test the concept and see what problems I would likely have. I have not made it because I was missing the metal I would need. By getting the blanks of the right size, I can make my cross slides when the opportunity presents itself.

We were celebrating a combined birthday of my brother and I. Our birthdays were just a week or two apart.

Mom and I gave my brother a new Saws-all that we got at a yard sale. He liked that it had a blade lock that did not use allen wrenches to hold the blade in place.

We both got gift cards and money. My gift cards were Home Depot and Sears. they will get well used.

Of course, everybody brought food and I ate far more than I should have. As soon as one of the Bar-B-Q meat was done, I would sample it. I later had a few more of them. I ate just a tiny bit of whatever was there and skipped most of it to keep from over-eating on stuff I don't need.

Tomorrow, I have some work to do around the house so I do not expect to be leaving the house at all.

I will see what I actually do tomorrow.

Monday

I stayed home and did very little. I did dig through two boxes (two years) of bills. I filled a garbage bag of papers and ended up with just a little I will keep. I still have to find my paper shredder.

The morning itch from working Bougainvillea is minor now. I did use an antihistimine this morning but both yesterday and today I have not taken any during the rest of the day. I may see if I can go without any tomorrow. I may well be over the allergic reaction to the wood sap.

Next week, I visit the antique shop and check in on what is going on there. I will be dropping off a single bowl to add to the collection I have on display. The bowl is that Sea grape bowl I added sand inlay.

Unless I come up with a wood working project, I may spend my weekend machining metal for my cross slide my little lathe needs. I do have lots of wood working projects but what excites me is what is important.

I will see what I actually do next weekend.

No comments:

Post a Comment